Scientists analyse feasibility of lightning-produced ammonia

PROMISING DEVELOPMENT Scientists are exploring the use of electricity to excite nitrogen and oxygen molecules and passing these molecules to membrane-based electrolysers as a way of producing ammonia

Scientists have developed lightning-produced ammonia in gas form – a new, more efficient method that is a step closer to the sustainable production of ammonia and, therefore, a transition to a hydrogen-based economy, says the University of Sydney school of engineering and biomedical engineering and the Net Zero Institute’s Professor PJ Cullen.

University of Sydney researchers have harnessed human-made lightning to develop a more efficient method of generating ammonia – “one of the world’s most important chemicals”. Ammonia is also the main ingredient of fertilisers that account for almost half of all global food production.

The team has successfully developed a “more straightforward method” to produce ammonia (NH3) in gas form. Previous efforts by other laboratories produced ammonia in a solution (ammonium, NH4+), which requires more energy and processes to transform it into the final gas product.

The current method to generate ammonia, the Haber-Bosch process, “comes at a great climate cost”, leaving a huge carbon footprint, the Sydney team notes. “It also needs to happen on a large scale and close to sources of cheap natural gas to make it cost-effective.”

The Process that Fed the World

Naturally occurring ammonia (mostly in the form of bird droppings), was once so high in demand it fuelled wars.

The invention of the Haber-Bosch process in the nineteenth century made human-made ammonia possible and revolutionised modern agriculture and industry. Currently 90% of global ammonia production relies on the Haber-Bosch process.

“Industry’s appetite for ammonia is only growing. For the past decade, the global scientific community, including our lab, wants to uncover a more sustainable way to produce ammonia that does not rely on fossil fuels.

“Currently, generating ammonia requires centralised production and long-distance transportation of the product. We need a low-cost, decentralised and scalable ‘green ammonia’,” Cullen says.

His team has been working on ‘green ammonia’ production for six years.

“In this research we’ve successfully developed a method that allows air to be converted to ammonia in its gaseous form using electricity. A huge step towards our goals.”

Ammonia contains three hydrogen molecules, meaning it can be used as an effective carrier and source of hydrogen as an energy source, even potentially as an effective means of storing and transporting hydrogen. Industry bodies have found they can access the hydrogen by ‘cracking’ ammonia to separate the molecules to use the hydrogen.

Ammonia is also a strong candidate for use as a carbon-free fuel owing to its chemical composition. This has caught the interest of the shipping industry which is responsible for about 3% of all global greenhouse-gas emissions.

Chemical Conundrum

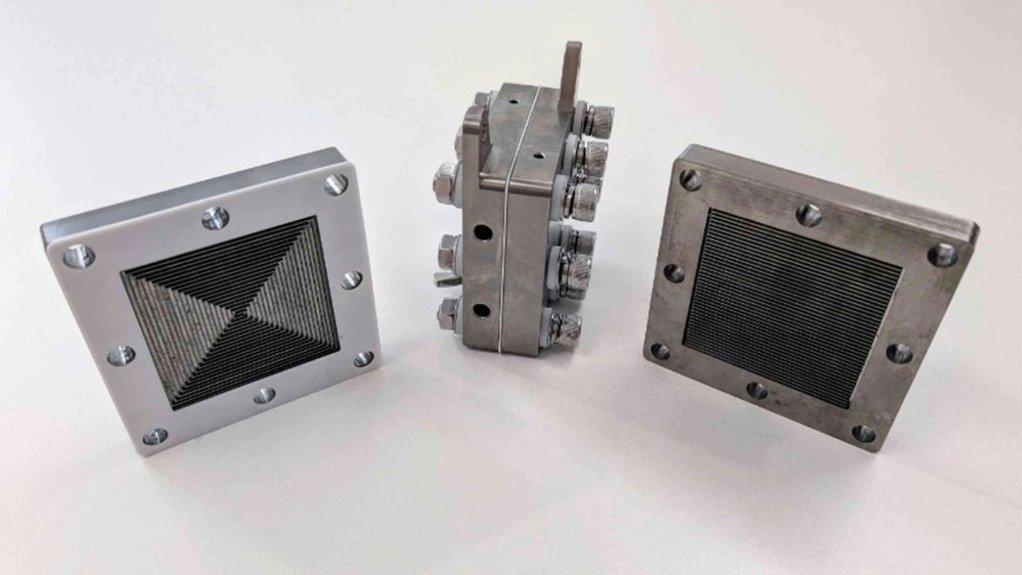

Cullen’s team’s new method to generate ammonia works by harnessing the power of plasma, by electrifying or “exciting” the air. However, the “star” of this process is a membrane-based electrolyser, where the conversion to gaseous ammonia happens.

During the Haber-Bosch process, ammonia is made by combining nitrogen and hydrogen gases under high temperatures and pressure in the presence of a catalyst.

The plasma-based method that Cullen’s team has developed uses electricity to excite nitrogen and oxygen molecules, which are passed to the membrane-based electrolyser to convert the excited molecules to ammonia.

Cullen says the findings signal a new phase in making green ammonia possible. The team is now working on making the method more energy efficient and competitive, when compared with the Haber-Bosch process.

“This new approach is a two-step process, namely combining plasma and electrolysis. We have already made the plasma component viable in terms of energy efficiency and scalability. To create a more complete solution, namely a sustainable ammonia product, we need to push the energy efficiency of the electrolyser component,” Cullen concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation